Call Us08045814681

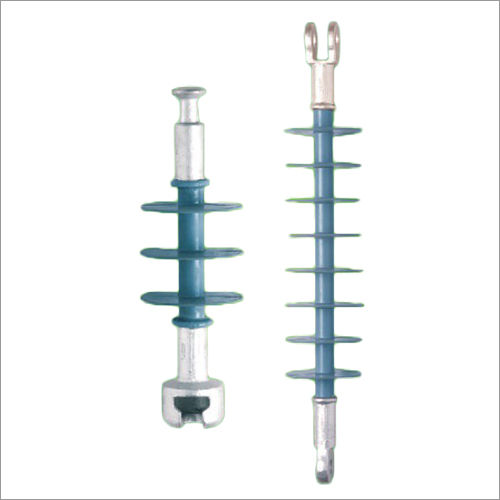

25KV Composite Insulators

100 INR/Number

Product Details:

- Surface Treatment Silicone coated

- Installation Guideline Mount vertically with appropriate hardware clamps and torque settings

- Size 120 mm x 40 mm

- Layer Multilayer

- Coating Type Silicone Rubber

- Feature Anti-pollution, High mechanical strength, UV resistant

- Thermal Conductivity 1.4 W/mK

- Click to view more

X

25KV Composite Insulators Price And Quantity

- 100 Number

- 100 INR/Number

25KV Composite Insulators Product Specifications

- 40 mm

- Porcelain

- Industrial

- 25KV Composite Insulators

- Gray

- 1.4 W/mK

- 2.4 Gram per cubic centimeter(g/cm3)

- -40C to +150C

- Multilayer

- 120 mm

- Anti-pollution, High mechanical strength, UV resistant

- Silicone Rubber

- 1.4 W/mK

- 250 MPa

- Mount vertically with appropriate hardware clamps and torque settings

- 120 mm x 40 mm

- Silicone coated

- 25 Volt (V)

- 28 kV

25KV Composite Insulators Trade Information

- 100 Number Per Month

- 8-10 Days

Product Description

We are an outstanding enterprise successfully committed in manufacturing and supplying excellent grade 25KV Composite Insulators for Railways in 9 Tonne, Stay arm hook & Bracket tube configurations. These units are manufactured under I EC 61109 & RDSO specifications TUSPC/OHE/INSCOM/1070 using supreme grade Polymeric/Silicone Rubber. Perfect to be connected to main electrical wires, the offered units ensure excellent protection from surges and short-circuit. In addition to this, our clients can purchase this 25KV Composite Insulators at highly competitive prices from us.

Features:

- The external sheds are moulded from Silicone rubber on the latest state of the art injection moulding machinery from Desma Germany.

- The end fittings are made up of malleable cast iron BM:350 of IS 14329 or SG cast iron conforming to grade 400/151 of IS 1865 iron and are duly Hot dip galvanized to a min of 750-10009/m2as per RDSO specifications.

- The fittings are crimped on microprocessor controlled automatic hydraulic crimping machines. Creepage distance offered is 1050 mm i.e. 20 mm/kV suitable for medium polluted areas.

Construction Features:

- The core is made up of fiber glass rod which is a insulating part of the composite insulator which ensures all the necessary mechanical characteristics. The FRP rod is one of core material which is manufactured by protrusion process using boron free ECR grade glass fiber haying required mechanical & electrical characteristics.

Design Tests:

- It has RDSO certification from Indian railways. They are also tested duly witnessed by RDSO engineer at our works. Further, the composite insulators have been extensively type tested as per the IEC/IS/RDSO specifications.

Quality Control:

- We have all the requisite infrastructure to carry out routine tests on the insulators as per the international/national standards such as Dry power frequency voltage test, Mechanical Tensile test, Thermo mechanical test chamber, U.V. weathering Rubber tensile test etc as per IEC 61109.

Outstanding Electrical Performance

Featuring a rated voltage of 25 kV and a flashover voltage of 45 kV, this composite insulator ensures safe and reliable power transmission. Its 630 mm creepage distance boosts performance under severe weather and pollution, making it suitable for diverse industrial environments.

Durable and Weather-Resistant Construction

Made from high-quality composite polymer with galvanized steel end fittings, the insulator withstands harsh conditions. Its permanent hydrophobic property and excellent arc resistance protect against moisture and electrical discharge, promising operational integrity and a service life of over 30 years.

Minimal Maintenance, Maximum Benefits

Engineered for industrial efficiency, this insulator requires minimal upkeep, reducing maintenance costs and downtime. Its robust construction and weatherproof design contribute to reliable long-term service, supporting various power infrastructure projects across India.

FAQs of 25KV Composite Insulators:

Q: How is the 25KV Composite Insulator installed in industrial applications?

A: The insulator is mounted using its galvanized steel end fittings, which ensure secure attachment to transmission and distribution structures. Professional installation by trained personnel is recommended for optimal safety and performance.Q: What benefits does the hydrophobic property of the insulator provide?

A: The permanent hydrophobic surface repels water, reducing the risk of surface leakage currents and minimizing contamination-related failures. This enhances the overall reliability of power transmission, especially in humid or polluted environments.Q: When should this composite insulator be considered over traditional porcelain types?

A: Choose this composite insulator when you require lighter weight, superior weather resistance, minimal maintenance, and higher arc resistance compared to conventional porcelain insulators. Its particularly suited for installations where reliability and longevity are top priorities.Q: Where can this 25KV composite insulator be used?

A: It is ideal for industrial power distribution and transmission networks, especially in regions with harsh weather or high pollution. Its versatile design makes it suitable for new installations or as a replacement for older insulators in substations and overhead lines across India.Q: What is the typical process for manufacturing this composite insulator?

A: The manufacturing involves molding a high-performance composite polymer, integrating galvanized steel end fittings, and subjecting the insulator to rigorous testing per IEC 61109 standards to ensure safety, durability, and electrical reliability.Q: How does superior arc and weather resistance benefit long-term usage?

A: Excellent arc and weather resistance mean the insulator remains effective despite exposure to electrical discharges and severe weather. This reduces the risk of outages, extends service life beyond 30 years, and lowers maintenance demands.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese